Treatment of metal bearings and small mechanical pieces in Bergamo.

Protective, thermal and surface treatment of metal components.

Metal treatments

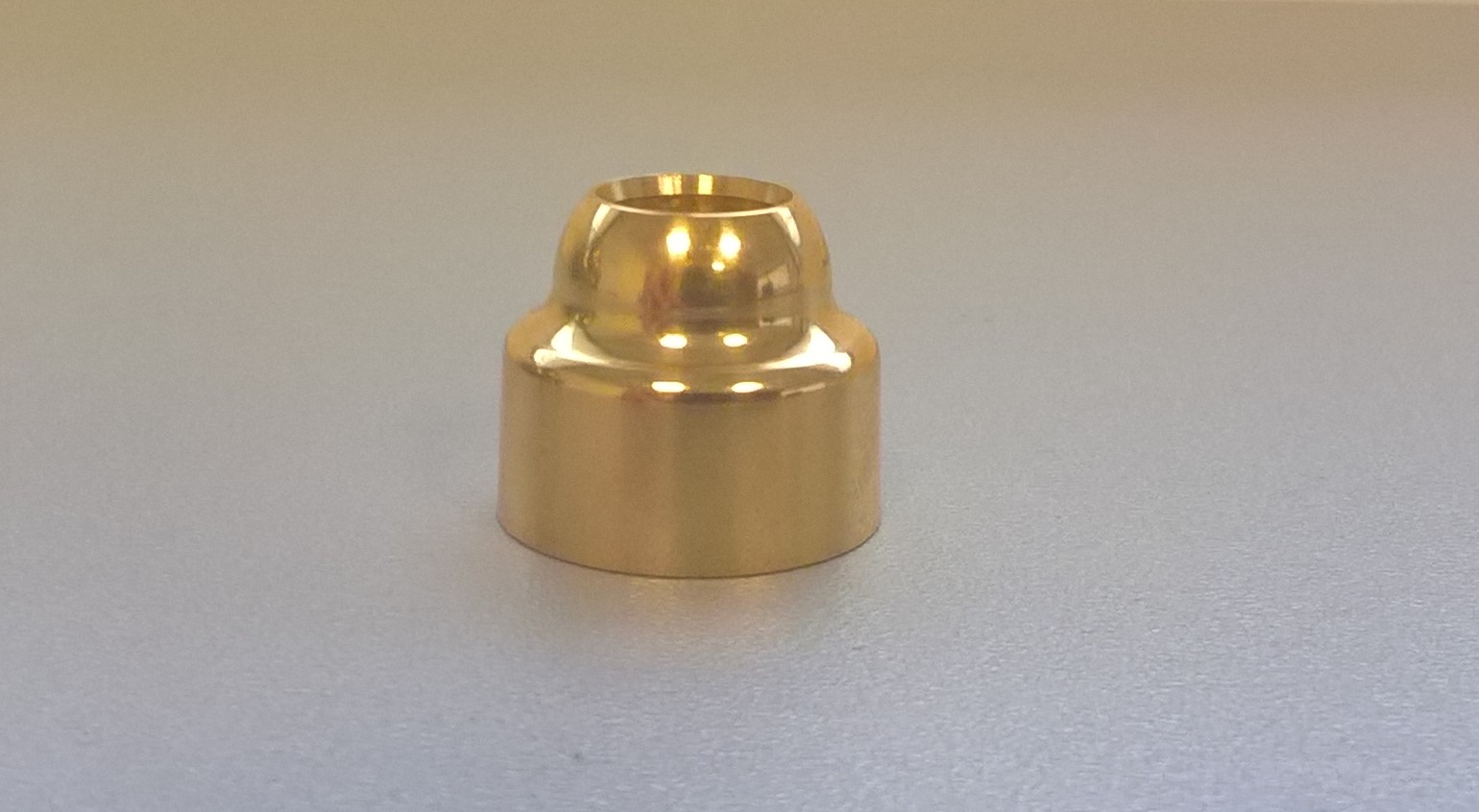

In its two workshops in Palazzago and Barzana in the province of Bergamo the metalworking company Erba Spa carries out a number of treatments for improving the characteristics and performance of its metal products such as fittings and small metal parts.

Thermal treatments

Erba Spa with its offices in the province of Bergamo carries out thermal treatments for the purpose of improving the mechanical characteristics of our products.

When we talk about thermal treatment we refer to operations in which the metal undergoes one or more thermal cycles, in other words, changes of temperature with varying times.

The purpose is to give the metals determined characteristics and/or properties that depend on their final use.

The thermal treatments we carry out on our products are in particular normalization, annealing, hardening and tempering.

Galvanic protection treatment

The metalworking company Erba Spa with offices in the province of Bergamo carries out galvanic protective treatments for the purpose of protecting the products from the phenomenon of corrosion.

The galvanic treatments are electrochemical deposits of a single layer of a metal or an alloy so that the properties of the surface of the support are modified from the technical and aesthetic point of view. Erba Spa’s workshops in Palazzago and Barzana supply products with protective treatments such as nickel plating, chromium plating, electrolytic galvanizing and zinc nickel plating.

Surface treatments

When requested by the client, at the end of the process we deal with the treatment of the metal bearings to improve their characteristics and to supply a finished product ready to use.

Specifically we deal with surface treatments of our bearings such as polishing, brushing, dressing, tumbling, sand blasting and applying scotch grip.